Not all structures are created equal and because of this we are often asked, “What makes the steel strength of Norseman products different?”

Not all structures are created equal and because of this we are often asked, “What makes the steel strength of Norseman products different?”

Significant factors influencing the safety and longevity of a building are the quality, thickness (gauge) and the total amount of steel used in a structure. One of the results of inadequate steel is called “web punching”. Web punching occurs when the truss webs punch through the walls of the truss chords if the steel in the truss chord is too thin. Thin steel can lead to truss chord buckling at the web connection location. This process is called “chord plastification”.

- Many manufacturers use the least steel possible when designing their buildings and often use thin gauge steel for their truss chords. Light gauge steel like this permits excess flexing of the truss and buckling at low web forces.

- Norseman Structures recognizes that undersized steel has the possibility to fail in this manner. To combat this, our designs require the use of larger diameter webs as well as thicker gauge steel in our truss chords, thus preventing any “punch through”.

- An effective way to compare building structures is by weight of the structural steel in the building. As it is unlikely a competitive design could be safely engineered using ten percent less steel than our buildings, it is likely the competitive design does not meet all building code requirements. Norseman Structures also utilizes heavy gauge steel in order to meet the needs of our customers.

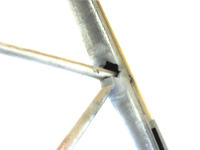

This picture shows an example of the dangers of “web punching”. As you can see, the truss webbing has ‘punched’ through the wall of the thin gauge steel likely causing a ripple effect throughout the rest of the structure. The end result of this unfortunate occurrence is at best an unusable building and at worst, a catastrophic failure causing a collapse.

This picture shows an example of the dangers of “web punching”. As you can see, the truss webbing has ‘punched’ through the wall of the thin gauge steel likely causing a ripple effect throughout the rest of the structure. The end result of this unfortunate occurrence is at best an unusable building and at worst, a catastrophic failure causing a collapse.

Web punching occurs when the truss webs punch through the walls of the truss chords if the steel in the truss chord is too thin.